Basic Seams and How to Use them in Sewing

- omemy tutorials

- Nov 13, 2021

- 6 min read

Updated: Jun 17, 2025

What is a seam? Is every line of machine stitch a seam?

A seam is a line of machine stitching that joins two or more layers of fabric together. Technically speaking, every seam is a line of stitch but every stitch line will not be a seam. We can find seams all over the garments we wear. The line of stitching running all along our sides, from top to bottom is the seam that not only joins the front and back of the garment together but also become a mechanism of providing shape to the garment. It is the seam that is adjusted and readjusted for adapting the fit of the garment. A seam has the capability of correcting many of the unintentional flaws in pattern cutting and also the possibility of spoiling the fit of a perfectly cut pattern piece. Seams are always placed on the wrong side of the garment (with some exceptions like French seam). This is done to ensure that outside of the garment looks clean. Remember, since seam is a permanent stitch, it is always locked at the beginning and end with a reverse stitch.

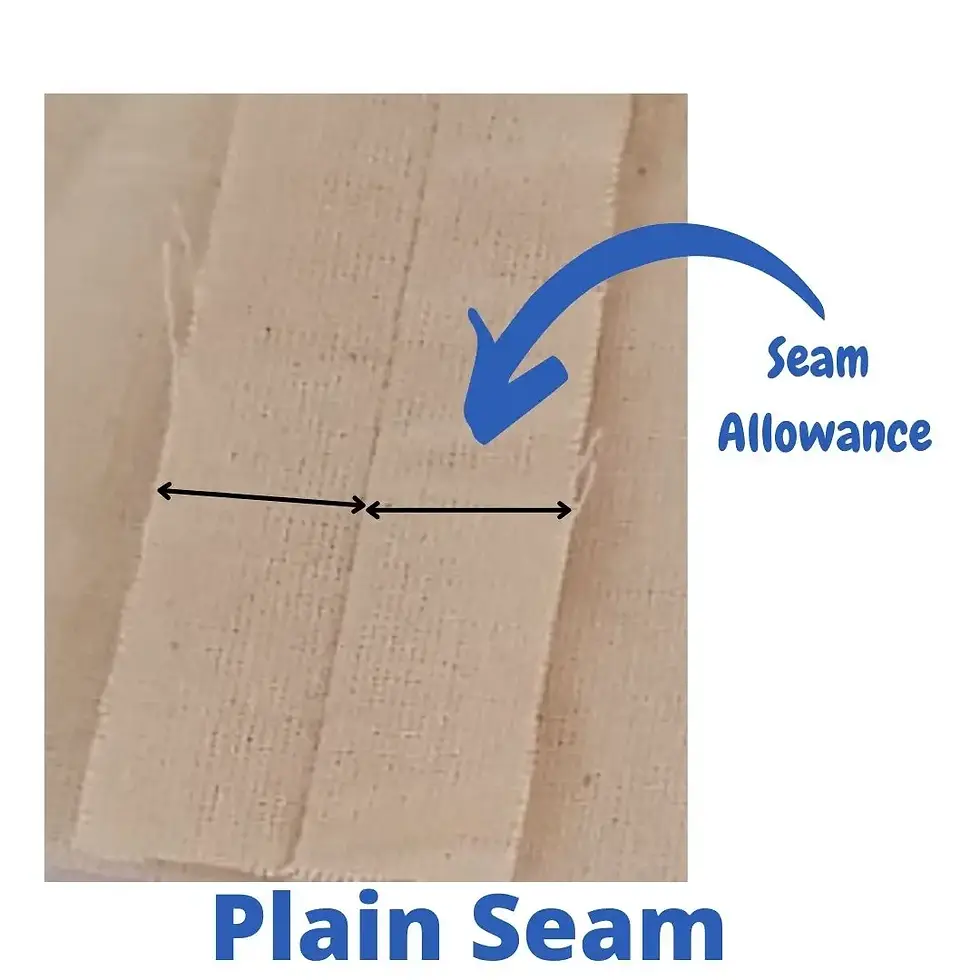

Seam Allowance: Seam allowance is the distance between the fabric edge and the seam line. Seam allowance can vary from 0.5cms to 1.5cms depending upon the requirement of the garment, fabric type and seam type.

Plain Seam: This is the simplest, quickest and most commonly found seam where two fabrics are joined together with a straight line of plain stitch. To place this seam, the fabric layers are placed right sides facing each other/inside and wrong sides of the fabrics facing outside. The seam is placed on the wrong side of the fabric. After the seam has been placed, the seam allowance on the back side is flattened/opened with one flap pressed on each side, like the wings of a butterfly. The raw edges of the plain seam allowance can then be left as it is or finished with one of these mechanisms.

· Pinking: Raw edges of the plain seam allowance can be cut with pinking shears that cut the raw edge in zig-zag manner. This neatens the seam allowance and also delays fraying.

· Hand/machine-overlock: can be done by performing hand overcasting OR Blanket Stitch OR machine overcasting over the raw edge of the seam allowance. The purpose here again is to delay fraying.

· Turn and stitch: The raw edge of the seam can be turned and stitched over itself to lock the raw edge and prevent fraying.

French Seam: French seam is a two-step seam that can used for various reasons. The raw edge of the seam allowance is stitched inside in French seam which ensures that it is not exposed. Therefore, this seam becomes very useful for fabrics that are prone to fraying. Also, sometimes the fabrics have some metallic/plastic yarns woven in for decorative purposes. These fabrics feel smooth on the surface but their raw edges could be pricky to the skin, especially after the skin is moistened with sweat & body heat. It is recommended to stitch the seams of all such fabrics in French seam. French seam is recommended for kids clothing for the same reason that it protects delicate kid’s skin from rashes caused by the raw edges of the seam allowance. This seam is also highly recommended for straight line garments like in A-line skirts. This kind of seam is not recommended for curved seams and seams for close fitting garments as the seam allowance is thicker than usual and might give a protruding feel to tight-fitting garments.

In French seam, the fabrics are laid wrong sides facing each other and right sides out for the first steps. Then a plain seam is placed with half a seam allowance than intended. Remember, as opposite to regular plain seam, here the seam is being placed on the right side. Then this seam is turned inside out and now second seam is placed on the original seam allowance, with right sides facing each other and wrong sides out. So finally, the seam gets placed on the wrong side and is not visible on the right side. However, there are no raw edges visible even on the wrong side of the fabric. This seam can only be differentiated from the wrong side, it looks exactly like plain seam on the right side. There are few techniques of modifying a plain seam into a pseudo-French seam by stitching the seam allowance together with raw edges turned in.

Run’n’fell / Flat felled Seam: This interesting seam can be most commonly found on intimate wear like bralettes and also infant clothing.

The characteristic feature of this seam is that the seam allowance is also stitched flat on the fabric with a second line of stitching that is even visible from the right side of the garment. This ensures that there is no protruding seam allowance left on the inside of the garment. This feature makes it suitable for intimate wear and infant wear.

To make this seam, first a plain seam is placed with right sides facing each other and wrong sides out, just the way we do for a basic plain seam. Thereafter, one of the two seam allowances is snipped into half. Now the wider seam allowance is folded over the narrow allowance (enclosing it’s raw edge) and the whole assembly is then folded over the base fabric. A seam is now placed on the outer edge/fold of this assembly so that it gets stitched over the base fabric to ensure that it would always lay flat. This seam is not suitable for bulky/thick fabrics as three layers of fabric are trapped inside the seam.

Lapped Seam: This is another interesting type of seam, largely used where the seam is expected to bear lot of stress or strain like the crotch areas of trousers.

The seam is commonly found in denims and other garments meant to sustain pulls. The idea is to divide the stress among three layers while the seam is still joining only 2 layers of fabric. This divides the amount of pull and prevents damage at seams. This seam is placed on the right side of the fabric and is a one-step process. To place this seam, a folded edge of one layer is placed over the marked stitching line on the right side of another layer, and a seam is placed on the edge of the fold. This seam is thus visible on the right side of the fabric.

Right side of fabric: The side of the fabric that is visible on the outer side of the garment is called the ‘Right side’. It is easier to identify the right side in printed, embroidered fabrics. However, in plain fabrics like calico or plain coloured fabrics it might get trickier at times to identify the right side of the fabric. In greige fabrics / unfinished fabrics, either sides can be assumed as the right side. However, in finished fabrics, one can look at the stenter holes on the fabric selvedge to identify the right side. Finished fabrics often have holes punched by the stenter frame hooks on both selvedges. The side with holes protruding up is generally the right side of the fabric. Although in solid dyed fabric there is uniform colour and feel on both sides, some functional finishes might have been only performed on the right side. The difference becomes significant after a few washes and might not be visible in a new fabric. Therefore, it is advisable to identify the right and wrong side before marking, cutting and stitching the fabric.

Wrong side of fabric: The side of the fabric opposite to the right side, the side that goes to the inside of the garment is called the ‘Wrong side’ of the fabric. All the markings on the fabric, the cutting line, stitching line are done on the wrong side of the fabric. This is to ensure that the right side of the fabric maintains utmost neatness. Also, most of the functional stitches and seams are placed on the wrong side of the fabric. Thus, it makes sense to mark the stitching line on the wrong side of the fabric.

Greige Fabric: A fabric that is still in the condition it was taken out of the loom and has not ben subjected to any finishing procedures like bleaching, singeing etc. is known as the Greige fabric. It has nothing to do with ‘Grey Colour’ as it is often confused with. This fabric is usually off-white in colour and has lower water absorbency as compared to other fabrics. Therefore, it is not good for dyeing and also is bound to experience some residual shrinkage on first contact with water. This is the most commonly used sampling fabric in production houses. Greige fabrics are commonly known as Calico in Europe & in Indian subcontinent it is known as Kora Kapda or Markeeen/Markin.

Selvedge: The thick ribbon running through the length on both sides of an open width fabric is called the selvedge. The direction of the selvedge is the same as the grain of the fabric and is often denoted by a double sided arrow on garment construction patterns.

-WebP.webp)

So very well explained

So very well explained